To making doing cable and tube easy-HOOHA

| HOOHA carbon steel welding pipe mills machine | ||||||

| Machine Type | Main shaft size | power | Welding power | Carbon steel diameter | Carbon steel thickness | Speed of production line |

| 20 carbon steel pipe machine | 45mm | 45kw*2 | 100kw | 7.8-20mm | 0.25–1.2mm | 120m/min |

| 38 carbon steel pipe machine | 45mm | 45kw*2 | 150kw | 12.7-38.1mm | 0.5-1.5mm | 110m/min |

| 50 carbon steel pipe machine | 50mm | 55kw*2 | 150kw | 25.4-50.8mm | 0.7-2.0mm | 100m/min |

| 63 carbon steel pipe machine | 60mm | 75kw*2 | 200kw | 31.8-63.5mm | 0.8-2.5mm | 90m/min |

| 76 carbon steel pipe machine | 70mm | 90kw*2 | 250kw | 38.1-76.2mm | 0.8-3.0mm | 80m/min |

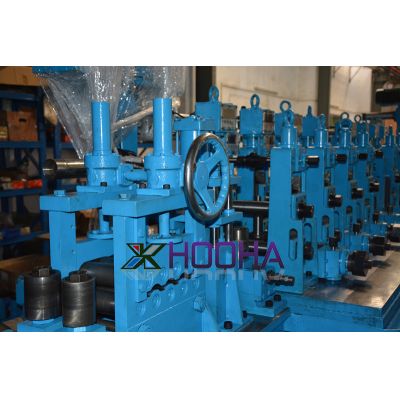

Carbon steel pipe making machine branch of HOOHA introduction:

1.Taiwan technical team 25 years working experience for carbon steel pipe making machine

2.Taiwan clients for carbon steel pipe production line over 100 production line over the world

3.10 production line manufacture each year for carbon steel pipe use

The machine main features:

Application Industrial and decoration

Production Capacity 20-80M/min

Place of Origin DONGGUAN, China (Mainland)

Brand Name HOOHA

Model Number HH32

Voltage According to customers’ requirements

Power(W) According to the actual machine

Dimension(L*W*H) According to the actual machine

Weight According to the actual machine

Certification ISO, CE

Warranty one year

After-sales Service Provided Engineers available to service machinery overseas

Product name Carbon Steel ERW Pipe Mill

Key word Pipe mill

Products Carbon steel pipe

Pipe material carbon steel

The thickness of steel strip 1.2-4.0mm

The width of steel strip 78-250mm

Processing steel pipe diameter 25-80mm

Color optional

Maximum weight coil 2500kgs

Pipe cutting length 4-8M

Product Description

1.1 Summary:

HH32 carbon steel welding pipe mill line is specially used for producing Φ12.7-Φ50.8mm,δ0.6-2.0mm high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe(δ≤1.5mm).

It made by refined materials in high precision and equipped with computer fixed length cutting saw.

The main machine including forming, welding cooling sizing and straightening device answer the use one installation bed.

The composition of equipment is from uncoiler to computer fixed length-cutting saw.

Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

1.2 Applicable material:

(1)Hot or cold-rolled steel strip (As per GB700-88 or GB1591-88)

(2)Material: Low-carbon steel, low alloy steelδs≤345Mpa, δb≤610Mpa

(3)The thickness of steel strip: 0.6-2.0mm (As per GB708-88)

(4)The width of steel strip: 40-160mm (±0.2mm)

(5)I.D. of steel coil: Φ450-Φ550mm

(6)O.D. of steel coil: Φ800-Φ1200mm

(7)Maximum weight coil: 1000kgs

1.3 Dimension range of processing steel pipe:

(1)O.D.: Φ12.7-Φ50.8mm

(2)Wall thickness: 0.6-2.0mm(square pipe and special-shaped pipeδ≤1.5mm)

(3)Length: 4-8m

Production Flow

1.4 Product (steel pipe) process flow of Carbon Steel ERW Pipe Mill:

Raw material (steel coil) → uncoiling → shearing and butt-welding → material accumulating → non-power leveling → mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → finished pipe→run-out table

Machine Parts

2.1 Uncoiler

2.2 Shearing and butt-welding machine

2.3 Vertical-type accumulator

2.4 Forming, welding and sizing unit

2.5 Computer-controlled tracking cutting saw

2.6 Finished pipe passing conveyor: (Run-out table)

Finished Products

Company information

Our service

1.Our engineers are avaiable to customers’ side for the training of the machine operation.

2.One year from the date when goods are shipped from China port. If the machines have any problem during the using process in guarantee period, firstly clients could ask for help by telephone, fax or email, HOOHA will assist to solve within 24 hours, if the problem still could not be solved, HOOHA could send maintenance staffs to clients site for free maintenance, the round trip air tickets cost and board and lodging expenses abroad of maintenance staffs should be undertaken by clients.

3.In the guarantee time, if the accessories are damaged by non-human factors, HOOHA will offer the accessories for free.

Reviews

There are no reviews yet.