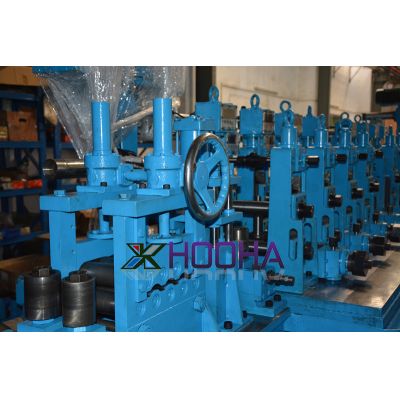

Steel ERW Welding Pipe Mill and Straight Seam Welded Pipe Production Line

1: The pipes made by our steel pipe making machine line

Pipe produced by our ERW pipe mill can be used for below:

- Oil & Gas Pipes 7. Wire and Cable Protection Pipe

2. Heating Pipe 8. Structural Support Steel Pipe

3. Low-pressure Process Pipeline 9. Industrial Steel Pipes

4. Low Pressure Fire Fighting Pipeline 10. Decoration Pipe

5. Sewage Pipes 11. Water Pipe

6. Steel Scaffolding Pipe 12. Building pipe

2: Our pipe production line installed in the world

HOOHA have successfully supplied world-class products and service to over 30 countries and areas around the world, such as: Poland, Spain, Russia, Yugoslavia, Ukraine, Turkey, Egypt, Saudi Arabia, India, Vietnam, Malaysia, Thailand, the Philippines, Pakistan, Kazakhstan, Ethiopia, etc.

Flow Chart

Standard flow chart of 2018 new Welding Plant Stainless Steel Easy Operate Pipe Making Machine :

Step 1: Un-coiler

Function: support rolled plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum, brake.

There are 3 types: pneumatic, hydraulic and manual.

Step 2: Shear & butt-welding

Function: Shear the end of each strip coil, then welding them together, so that pipe making welding machine line can be continue production.

2 Types: Automatic & manual

Step 3: Vertical Accumulator

Function: storage strip to keep continue production for the machine to make metel tube.

Type: Vertical

Advantage: easy to operation, low investment. special for small size and light wall pipe

Disadvantage: less storage capacity, crease.

Step 4: Horizontal Accumulator

Function: storage strip to keep continue production for the Round Square Pipe Making Machine Production Line.

Type: Horizontal

Advantage: Large capacity.

Disadvantage: more expensive than vertical type

Step 5: Forming section

Function: forming the tube from strip

Advantage:

>Advanced forming technical

>One-stage molding platform

>Reliable quality gear box

>Siemens Beide motor

Step 6: High Frequency Welding

Function: Welding the pipe , different thickness & diameter, the power of the HF welding machine welder

Our advantage: We choose the China best welder: Sanyi brand.

Step 7: Sizing section of pipe making machine

Function: sizing the tube to precise size

Advantage:

>Advanced sizing technical

>One-stage molding platform

>Reliable quality gear box and Siemens Beide motor

>High precision, low error of the pipe size

Step 8: Flying saw

Function: cutting the tube mill line tube to right length.

Advantage: easy to operation, low investment.

Disadvantage: loud, cutting section generates burr.

Step 9: Cold saw cutting of ERW tube mill line

Function: cutting the tube to right length.

Advantage: No noise, no burr cutting precision and cross section .

Disadvantage: the price is 4 times of ordinary flying saw.

Step 10: Run Out Table.

Function: run out the pipe, packing the pipe for tube making machine

Type: Automatic or manual

Main specification

Below is HOOHA standard series of our steel pipe making machine., HOOHA also accept customized.

| HOOHA carbon steel pipe making machine | |||||||||

| NO. | Model | Round tube | Sq.Rec Tube | speed m/min | Major Motor power/KW | High frequency power/KW | |||

| diameter/mm | Thickness/mm | Max.sq.size/mm | Max.Rec.Size/mm | Thickness/mm | |||||

| 1 | HH12 | 8.0-16 | 0.3-1.0 | 12*12 | 10*14 | 0.3-0.8 | 20-100 | 30.0 | 100.0 |

| 2 | HH16 | 8.0-25 | 0.3-1.0 | 20*20 | 15*25 | 0.3-0.8 | 20-100 | 30.0 | 100.0 |

| 3 | HH25 | 8.0-32 | 0.4-1.3 | 25*25 | 20*30 | 0.4-1.0 | 20-100 | 45.0 | 100.0 |

| 4 | HH28 | 10-40 | 0.5-1.5 | 30*30 | 20*40 | 0.5-1.2 | 20-90 | 75.0 | 150.0 |

| 5 | HH32 | 13-50 | 0.6-2.0 | 40*40 | 30*50 | 0.6-1.5 | 20-90 | 110.0 | 150.0 |

| 6 | HH32L | 16-63 | 0.6-2.0 | 50*50 | 40*60 | 0.6-1.5 | 20-90 | 110.0 | 150.0 |

| 7 | HH50 | 19-63 | 0.8-2.5 | 50*50 | 40*60 | 0.8-2.0 | 20-90 | 132.0 | 150.0 |

| 8 | HH50L | 19-76 | 0.8-2.5 | 60*60 | 40*80 | 0.8-2.0 | 20-90 | 160.0 | 200.0 |

| 9 | HH60 | 21-76 | 1.0-3.2 | 60*60 | 40*60 | 1.0-2.5 | 20-80 | 185.0 | |

Reviews

There are no reviews yet.